LDPE is an abreviation for Low Density PolyEthylene. King KPC low-density polyethylene is produced with our proprietary K-Stran™ process for unsurpassed flatness and quality up to 1-1/2” in thickness. For gauges up to 4”, our state-of-the-art compression molding system is utilized to create the same quality slabs. We also use a proprietary process that makes massive shapes. King KPC LDPE extruded sheets are very pliable with a low Durometer of 42, and a smooth soft translucent appearance. King KPC LDPE uses a special formulation with the finest FDA and USDA approved materials. Stock sheet is ideal for applications such as stencils, orthopedics, packaging, sound deadening, and the automotive industry. Other applications may include trays, general-purpose containers, food storage, laboratory containers, and corrosion-resistant work surfaces. KPC LDPE sheets are also used for applications where corrosion resistance is a factor but stiffness, high temperatures and structural strength are not.

We also offer our King KPC LDPE in a special grade, which is certified as a barrier material or radiation shielding on nuclear naval warships, submarines and certain medical applications. King Plastic Corporation is certified by prime vendors of the U.S. government as the source for type V neutron shielding material. Our processes, materials, quality programs, sampling testing, and packaging all meet or exceed military specification MIL-P-23536A. King KPC LDPE is RoHS compliant.

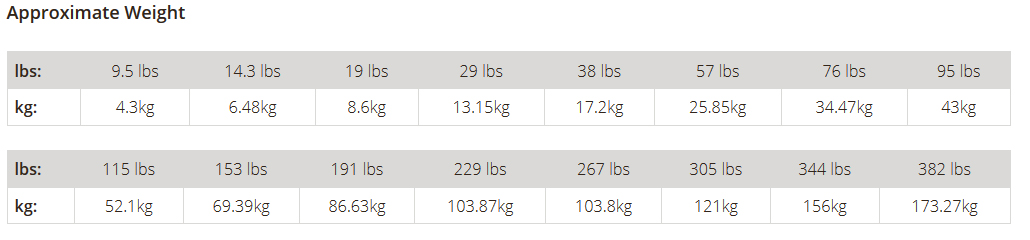

Standard Sheet size is 48″ x 96″.