ABS is derived from Acrylonitrile, Butadiene, and Styrene. The advantage of King Plastic Company (KPC) ABS is that this material combines strength and rigidity of the acrylonitrile and styrene polymers with the toughness of the polybutadiene rubber. A variety of modifications have been made to improve impact resistance, toughness and heat resistance. The impact resistance does not fall off rapidly at low temperatures and stability under load is excellent with limited loads. KPC ABS is considered superior for its hardness, gloss, toughness, and electrical insulation properties. KPC ABS is easily machinable and available in smaller sizes. It is extensively used in prototyping, the modeling industry and other mechanical applications.

ABS is derived from Acrylonitrile, Butadiene, and Styrene. The advantage of King Plastic Company (KPC) ABS is that this material combines strength and rigidity of the acrylonitrile and styrene polymers with the toughness of the polybutadiene rubber. A variety of modifications have been made to improve impact resistance, toughness and heat resistance. The impact resistance does not fall off rapidly at low temperatures and stability under load is excellent with limited loads. KPC ABS is considered superior for its hardness, gloss, toughness, and electrical insulation properties. KPC ABS is easily machinable and available in smaller sizes. It is extensively used in prototyping, the modeling industry and other mechanical applications.

ABS has good chemical and stress cracking resistance to inorganic salt solutions, alkalis, acids, and some oils. ABS also has excellent abrasion resistance, electrical properties, moisture and creep resistance.

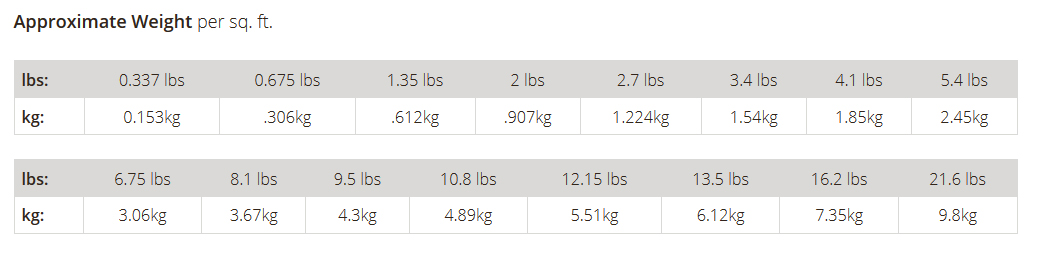

NOTE: Standard Sheet Sizes are 48″ x 96″.

* Colors may vary depending on monitor settings. Please consult actual samples to verify true colors.

- Automotive Parts

- Industrial Enclosures

- Machine Parts

- Prototype Modeling

- Short Run Production Parts

- Air Conditioner Components

- Industrial Enclosures

- Shelving

- Switches

- Transformer Housings